- Home

- Pentair - Membrane plus approach

ACHIEVING EXCELLENCE WITH MEMBRANE+

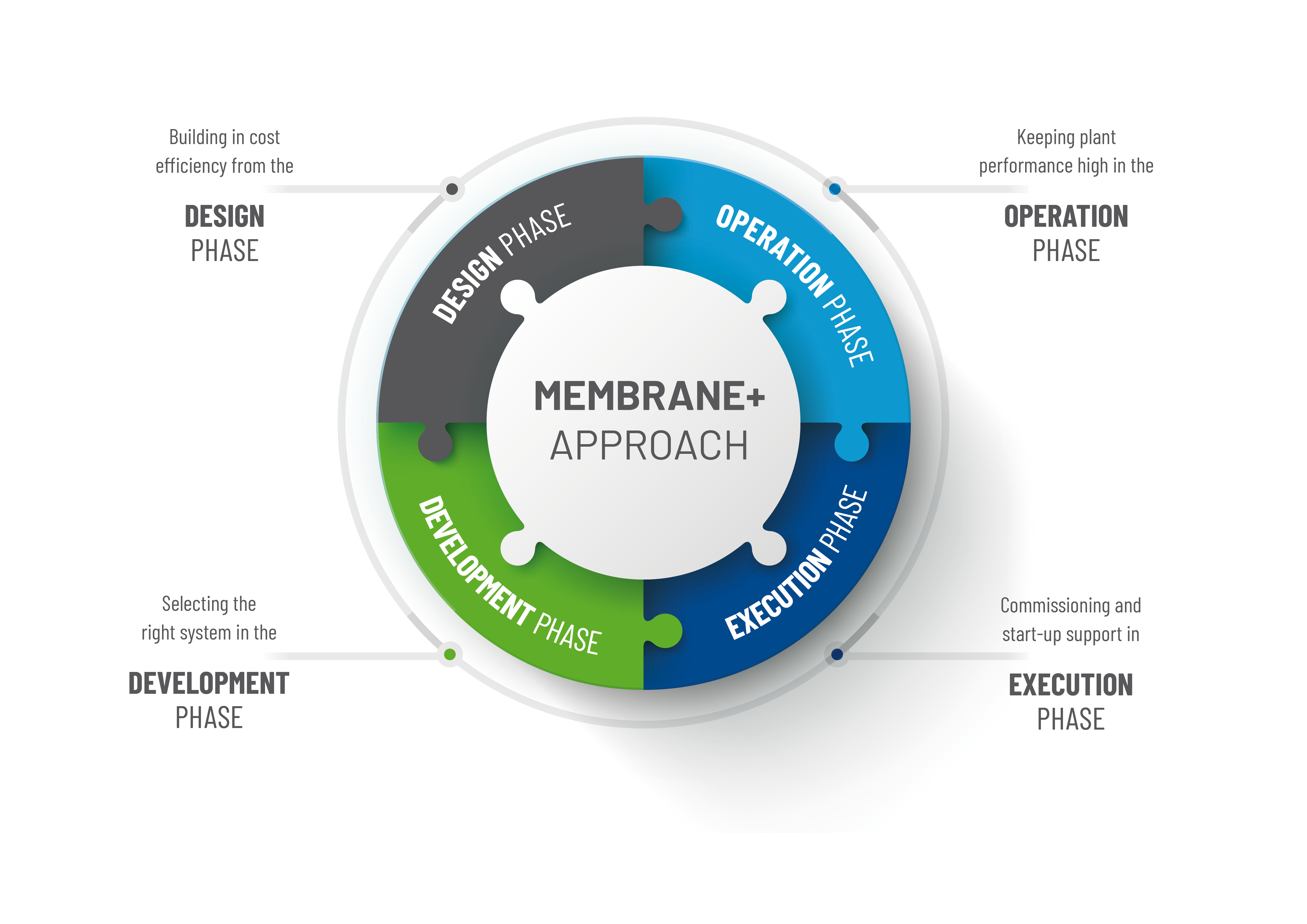

At X-Flow we believe membrane technology is essential in purification and filtration processes, now and in the future. We aim to maximize results for our partners. X-Flow uniquely combines high-quality membranes with outstanding implementation know-how. We call it our Membrane+ approach.

Membrane+ approach provides technological support to OEMS and contractors in every project phase. This expert assistance, especially when provided from an early stage onward, makes the difference in terms of quality, safety, efficiency and reliability.

Our Membrane+ Approach offers you multiple advantages and clear benefits:

- Mitigates engineering and implementation risks

- Ensures cost optimization during the plant design phase

- Avoids design errors and changes in the execution phase

- Ensures first-time-right project delivery

- Ensures a smooth takeover by your customer

Pentair X-Flow: Membrane+ approach

We believe membranes are essential in the purification and filtration processes of today and tomorrow. Apart from high-quality membranes with the lowest cost of ownership and the highest efficiency, we offer our partners and customers the technical support they need in every project stage from design to handover. We call it the Membrane+ approach.

SUPPORT IN EVERY PHASE OF YOUR PROJECT

Membrane+ is our approach to helping partners solve any specific project-related issue. Our engineers are committed to provide all the practical support required in every project phase from conceptual design to piloting, startup and beyond. We provide you customized services throughout every phase of your membrane filtration project:

DEVELOPMENT PHASE

When using membrane technology to provide the right solutions for your customers’ challenges, it is crucial that your engineers have the right design skills and application know-how. Our Pentair University offers advanced education in membrane engineering.

DESIGN PHASE

Our Sales Engineering department contributes to a smooth bid validation by fine-tuning all project parameters and verifying the technical and commercial feasibility of your full-scale membrane plant.

EXECUTION PHASE

Your membrane plant can only deliver the expected performance when every membrane is part of a system carefully designed and dimensioned, as well as properly built, commissioned and operated.

During the execution phase, X-Flow process engineers build the backbone of your system.

OPERATION PHASE

When the project is completed and water flows through the membranes as intended, we can offer the kind of after sales support that helps to keep plants in optimal working condition as long as technically possible, like:

X-Flow uniquely combines high-quality membrane products with outstanding implementation know-how. Our specialized engineers contribute to your flawless operation of your filtration installations. Their experience makes the difference in terms of quality, safety, efficiency and reliability. Together we maximize your results. If you are interested to know more about our Membrane+ Approach, please fill in the contact form.

CASE STUDY SWEDEN

Read our case study about a state-of-the-art drinking water plant in Sweden. In a process of close cooperation, the Kungalv municipality, process partners and Pentair engineers went through every step of the Pentair X-Flow Membrane+ Approach from development to operational excellence.