Product Information

Haffmans CO2 Recovery Unit (CRU) is a robust and reliable CO2 recovery solution for a wide variety of brewery needs ranging from 300,000 to beyond 5,000,000 hl/yr.

BE CO2 SELF-SUFFICIENT

CO2 Recovery Unit (CRU) is a robust and reliable CO2 recovery solution for a wide variety of brewery needs ranging from 300,000 to beyond 5,000,000 hl/yr. It is the benchmark CO2 recovery plant in the global brewing industry with 25-year-old plants still running strongly.

The CRU-program comes with a range of options from cost-effective conventional CO2 recovery plants to plants incorporating the latest technologies. Each CRU plant is an individual jewel: We listen carefully to your needs and design (y)our CRU to your specific requirements. Not much space available for a new plant or retrofit: No worries, our engineers will find a solution for the most restricted space conditions.

The purity of the liquid CO2 end product exceeds general quality standards for food/beverage/ingredient purposes including the latest edition of the ISBT standard. Recovering your own CO2 lowers your site’s CO2 footprint and reduces your VOC emissions to the atmosphere. Both contribute to a more sustainable operation.

Worldwide, customer-specific solutions will be installed and commissioned by a team of experienced and well-trained service engineers. But the dedication to your CO2 self-sufficiency continues after the commissioning. Through comprehensive lifecycle management, our technical support and service team ensures that your CRU operates optimally.

Benefits

- CO2 self-sufficiency and beyond

- High quality liquid CO2 ≥ 99.998 % v/v, O2 ≤ 5ppm v/v

- High recovery efficiency even at low CO2 inlet purity with ≥ 95% v/v

- Robust design for reliable 24/7 operation, uptime ≥ 95%

- Flexible, modular setup to meet site’s layout needs

- Natural refrigerants CO2 (R744) and NH3 (R717) applied

- Early recovery and up to 60 % energy savings with LiquiVap (optional)

- Access to CO2 knowhow and technical support

-

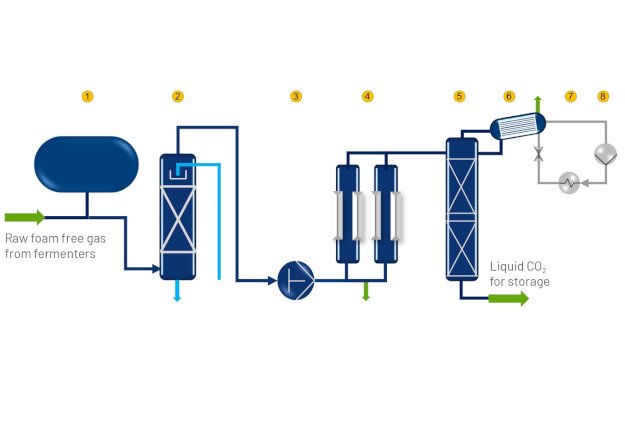

PROCESS DESCRIPTION

-

Raw foam-free fermentation gas is fed to the plant where it is buffered in a balloon (1) and scrubbed of water-soluble contaminants such as ethanol in the gas washer (2). A 2-stage dry running CO2 compressor unit (3) increases the gas pressure to 18barg (261psig) removing condensate in the process. The remainder of the impurities and water are then removed in the dual activated carbon filter and drier unit (4). Regeneration of this unit is automatic utilizing heating elements and dry CO22 purge gas. CO2 liquefaction takes place in a refrigerant cooled condenser (6) which includes refrigerant condenser (7) and refrigerant compressor (8). O2 is removed in the stripper (5). The purified liquid CO2 end product is transferred to the onsite storage tank.

-

OPTIONS

-

- Gas boosters

- Aerosol washers

- LiquiVap – early recovery and energy-saving system

- Liquid CO2 storage tank

- Ambient air or Glycol heated vaporizer

- Cylinder filling unit

- Road tanker pump

- Quality control equipment

- Installation and commissioning services

- Original spare parts

- After Sales Services

Downloads

| Title | Download PDF | |

| Product leaflet | CO2 Recovery Plant - Haffmans CRU | Download |

| Product leaflet | CO2 Recovery Plant - Haffmans CRU (German) | Download |

| Case study | Praxair Distillery | Download |

| Technical documentation | Looking for operating instructions, installation manual, spare part list etc.? | Please, send us your request |

RELATED PRODUCTS

HAFFMANS CO2 RECOVERY PLANT - CO2MPACTBREW

CO2mpactBrew is a CO2 recovery plant especially designed for smaller, craft-sized breweries with capacity 50.000-350.000 hl/yr.

HAFFMANS CO2 RECOVERY - SYSTEM ENERGY SCAN

Scan your CO2 Recovery Systems with Haffmans and get detailed information on energy consumption, performance and quality.

HAFFMANS CO2 RECOVERY PLANT - ECO2BREW

ECO2Brew is unique in its design to recover CO2 from fermentation processes at larger 24/7 operating breweries, over 2,000,000 hl/yr.

CO2 HARVESTING, COLLECTION & RECOVERY

For breweries wanting to take a strategic step towards self-sufficiency with CO2 Recovery, harvesting and collection technology is needed to bring the CO2 from the fermentation area to the CO2 recovery system. This technology also helps to mitigate the release of excess CO2 into the atmosphere during fermentation by capturing it at its source for CO2 recovery.