Achieve CO2 Self-Sufficiency

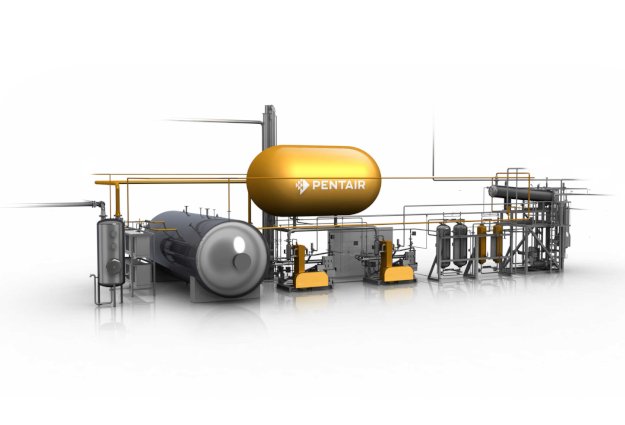

Recover CO₂ from your fermentation process with the Pentair Haffmans CO₂ Recovery System, allowing you to repurpose it back into your beverage production cycle and become CO₂ self-sufficient.

- Recover CO₂ from your own, known source (fermentation).

- Reduce the environmental impact of transporting CO₂ to your site.

- Lower your exposure to volatile market prices and supply risks.

WHO CAN BENEFIT FROM CO2 RECOVERY?

- Breweries (small to large)

- Distilleries

- Cideries

- Wineries (sparkling wine and wine production)

- Natural and sparkling water producers

CO2 Quality

The Pentair Haffmans CO₂ Recovery System has been designed to remove various impurities utilizing proprietary technologies.

Our systems can produce CO₂ with a purity higher than 99.998% v/v and with less than 5 ppm oxygen (O₂ ) v/v content, even at very low raw gas CO₂ purities.

BENEFITS

REDUCE CO2 SUPPLY RISKS AND COSTS

- Recovering your CO2 from your fermentation source or natural water spring can be more cost-effective than purchasing commercial CO2.

- Utilize excess CO2 for packaging/filling/bottling/canning/kegging other (non-beer) carbonated beverages onsite, sparkling water, cider, or sparkling wine

- Export recovered beverage-grade CO2 and generate additional revenue

SELF-SUFFICIENCY

- Avoid potential volatile pricing and supply risks.

CO2 QUALITY

- Produce beverage-grade CO2.

- Lower risk of using commercial CO2 from unknown CO2 sources.

SUSTAINABILITY AND COMPLIANCE

- Improve your CO2 footprint and meet corporate sustainability targets.

- Comply with local Clean Air Acts by reducing VOC emissions into the atmosphere.

Learn More

PENTAIR SCOPE OF TECHNOLOGY

| Harvesting | Collection | Recovery | Storage | Vaporization | Consumption |

| Pentair Tank Top Valve Technology | Pentair Südmo Double-Seat Valve Gas Manifold | Pentair Haffmans Recovery Systems | Pentair LiquiVap | Pentair Haffmans Quality Control Equipment |

How Tennent's Brewery Collects & Recovers Its Own CO2

Tennent’s required a fully end-to-end CO2 collection and recovery system, allowing them complete autonomy over recovering their CO2 and the capability to utilize it back into the beer production process.Watch to find out how Pentair helped Tennent’s to collect and recover its own supply of CO2 for their brewing processes.

RELATED PRODUCTS

CO2 HARVESTING, COLLECTION & RECOVERY

For breweries wanting to take a strategic step towards self-sufficiency with CO2 Recovery, harvesting and collection technology is needed to bring the CO2 from the fermentation area to the CO2 recovery system. This technology also helps to mitigate the release of excess CO2 into the atmosphere during fermentation by capturing it at its source for CO2 recovery.

HAFFMANS CO2 RECOVERY PLANT - ECO2BREW

ECO2Brew is unique in its design to recover CO2 from fermentation processes at larger 24/7 operating breweries, over 2,000,000 hl/yr.

HAFFMANS CO2 RECOVERY PLANT - CO2MPACTBREW

CO2mpactBrew is a CO2 recovery plant especially designed for smaller, craft-sized breweries with capacity 50.000-350.000 hl/yr.

HAFFMANS CO2 RECOVERY PLANT - CRU

Robust and reliable CO2 recovery solution for a wide variety of brewery needs ranging from 300,000 to beyond 5,000,000 hl/yr.

DOWNLOADS

| Title | Download PDF | |

| Case Study | CO2 Recovery Unit: CO2 Collection & recovery at Bulmers IE | Download |

| Case Study | CO2mpactBrew: Craft sized solution at Maui Brewing US | Download |

| Case Study | CO2 Recovery Unit: CO2 recovery at cindery Mosterei Möhl CH | Download |

| Case Study | CO2 Recovery Unit: Complete CO2 solution at Molson-Coors GB | Download |

| Case Study | Haffmans CO2 Recovery - SAB Miller Pilsen CZ | Download |

| Case Study | ECO2Brew: Water-free CO2 recovery at Lion Brewery LK | Download |

| Case Study | Haffmans CO2 Recovery - Praxair distillery | Download |

| Technical documentation | Looking for operating instructions, installation manual, spare part list etc.? | Please, send us your request |